Thermally conductive silicone gel and thermally conductive silicone grease are thermal interface materials. Thermally conductive silicone is thermally conductive RTV adhesive, a potting compound that can be cured at room temperature, and thermally conductive silicone grease is the biggest difference is that thermally conductive silicone can be cured, there is a certain degree of adhesive properties.

There is a material called thermal conductive film in the industry, generally used for certain electronic parts and chip surfaces that generate less heat. The thermal conductivity of this material is relatively small, and the thermal conductivity is generally low.

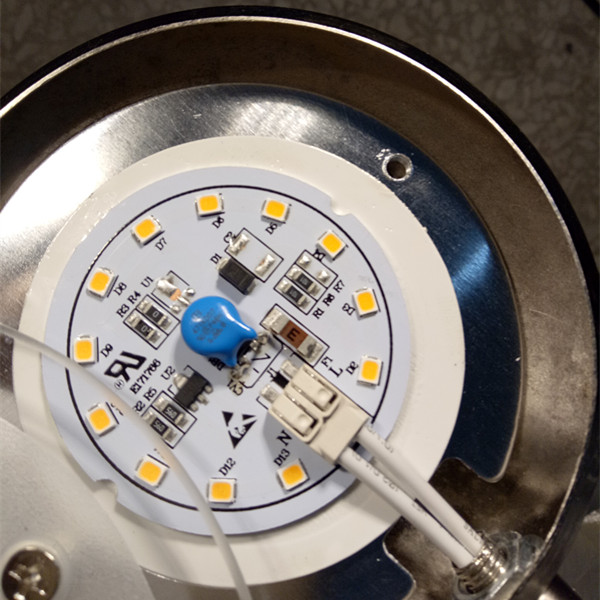

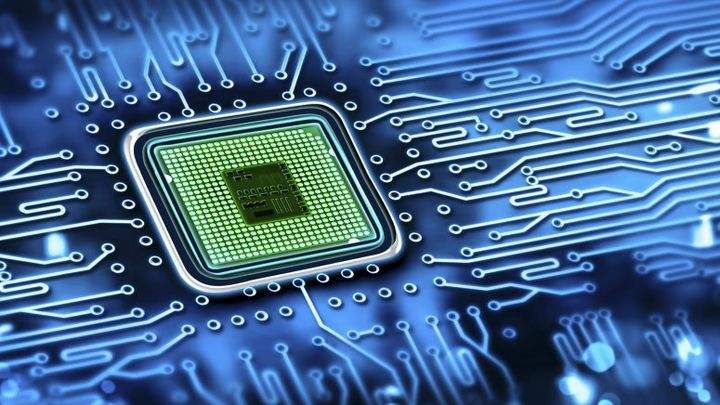

Thermally conductive silicone grease is one of the materials used to fill the gap between the CPU and the heatsink, which is also called thermal interface material. Its role is to conduct the heat emitted by the CPU to the heatsink, so that the CPU temperature is maintained at a stable working level, preventing the CPU from being destroyed due to poor heat dissipation and prolonging its service life.

In the application of heat dissipation and thermal conductivity, even if the surface is very clean two planes in contact with each other there will be gaps, these gaps in the air is a bad conductor of heat, will hinder the conduction of heat to the heatsink. Thermal silicone grease is a kind of can fill these gaps, so that the heat conduction more smooth and rapid material.

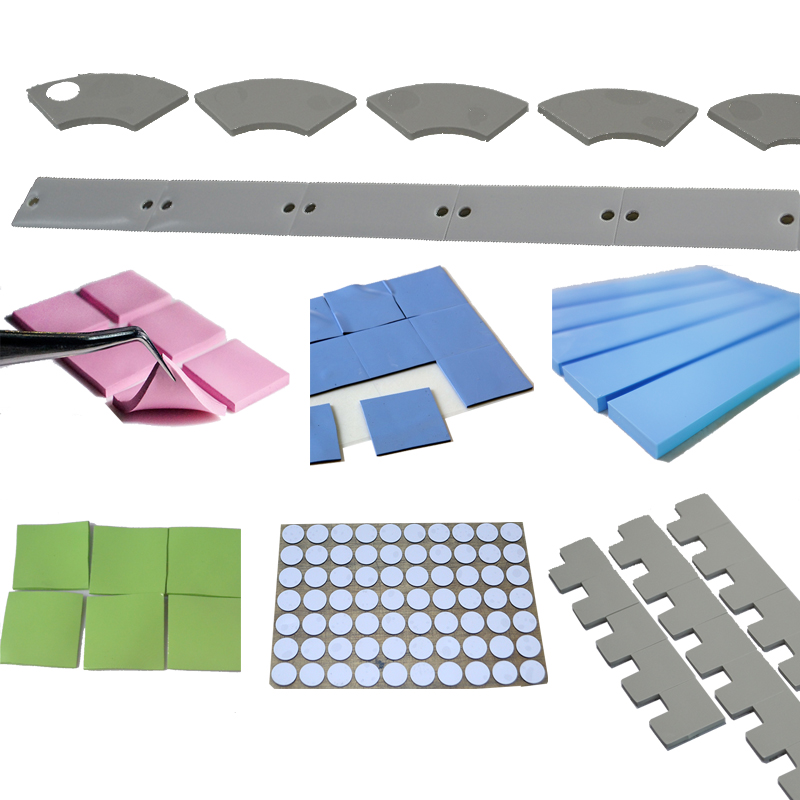

There are many types of silicone grease on the market today, and different parameters and physical properties determine different uses. For example, some are suitable for CPU heat conduction, some are suitable for memory heat conduction, some are suitable for power supply heat conduction ... ...

There are also some electronic products, power supply cooling, sensors, such as rapid temperature measurement can be used.

Thermally conductive silicone grease working temperature, generally not more than 200 ℃, high temperature up to 300 ℃, low temperature is generally -60 ℃ or so!

Thermally conductive silicone grease is a highly thermally conductive insulating silicone material, almost never cured, can be used in the -50 ℃ - +230 ℃ temperature for a long time to maintain the state of the paste. It has both excellent electrical insulation and excellent thermal conductivity, as well as low oil separation (tends to zero), high and low temperature resistance, water resistance, ozone resistance, weather aging resistance,. It can be widely coated in a variety of electronic products, electrical equipment in the heat-generating body (power tubes, silicon controlled, electric heat pile, etc.) and heat dissipation facilities (heat sinks, heat sinks, shells, etc.) between the contact surface of the role of the heat transfer medium and moisture-proof, dust-proof, corrosion-resistant, anti-vibration and other properties. Suitable for microwave communications, microwave transmission equipment, microwave special power supply, voltage regulator power supply and other microwave devices such as the surface coating or the whole potting, such silicon materials for the generation of heat to the electronic components, providing excellent thermal conductivity. Such as: transistors, CPU assembly, thermistors, temperature sensors, automotive electronic parts, automotive refrigerators, power modules, printer heads, etc..

Dobon firmly believes that quality is the soul of products, and strictly abides by every standard, every process of production, and every detail of service!

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.