With the increasingly powerful functions of electronic devices and the increase in integration density and volume reduction of electronic components, the requirement for device operation time is becoming longer. The increase in device temperature causes the slowing down of operation speed, mid-term failures, and other performance-related problems, causing greater impact. Therefore, how to effectively dissipate the heat generated by a greater unit power in a limited space becomes an urgent issue.

So, how do we select the right thermal conductivity material for a device component, considering other performance requirements in addition to thermal conductivity? Firstly, we need to have a simple understanding of the performance of various thermal conductivity materials.

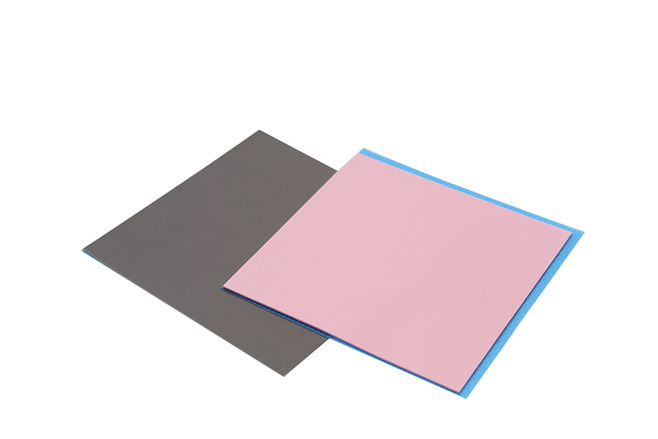

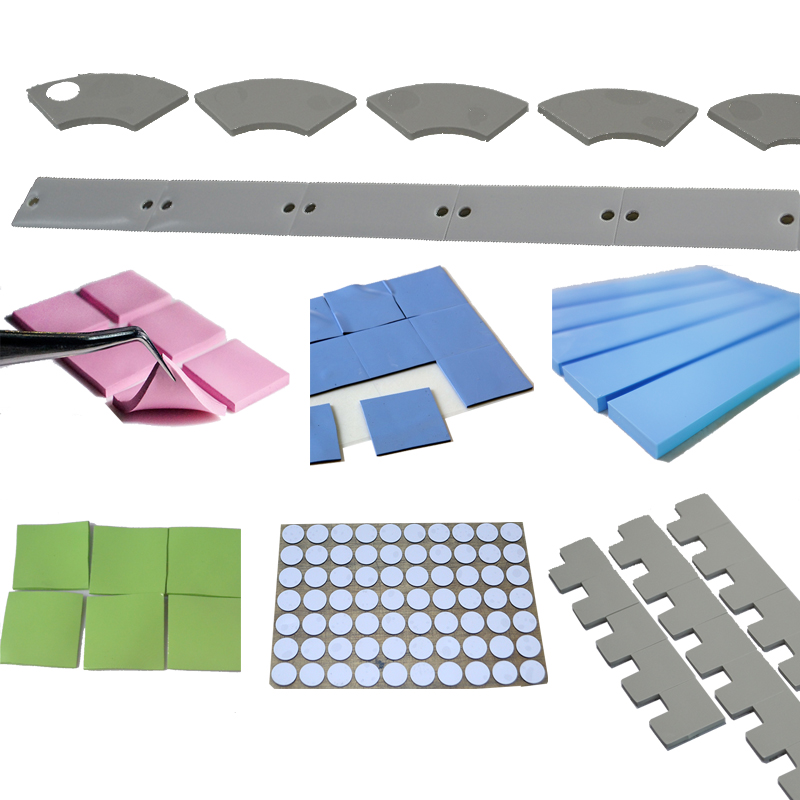

1、Thermal conductive silicone film: Thermal conductive silicone film is a widely used thermal conductive and insulating material. It has excellent properties such as flexibility, insulation, compression resistance, natural surface viscosity, and can also play a role in insulation, shock absorption, and sealing while completing the heat transfer between the heating and cooling parts. It has excellent processability and practicality, and a wide range of thicknesses, making it an excellent thermal conductive filling material. In order to meet the requirements, it can be attached with glue to enhance the viscosity, attached with film to enhance the insulation capacity, and reinforced with glass fiber to enhance puncture resistance.

2、Heat-dissipating graphite film: or thermal conductive graphite film, is currently the most popular thermal conductive material in the consumer electronics market, widely used in industries such as smartphones, tablets, LEDs, and switches. Made from natural graphite through complex processing procedures, the thermal conductivity and heat dissipation performance of the thermal conductive graphite film are excellent, mainly used to transfer the heat from the point and evenly spread it to the surface. The thermal conductive graphite film itself is also an excellent conductive material. Of course, now many applications will attach glue or film to meet the requirements of fixing and insulation. Xiaomi's initial use of thermal conductive graphite film as a selling point for advertising in smartphones shows the popularity of thermal conductive graphite films among the general public.

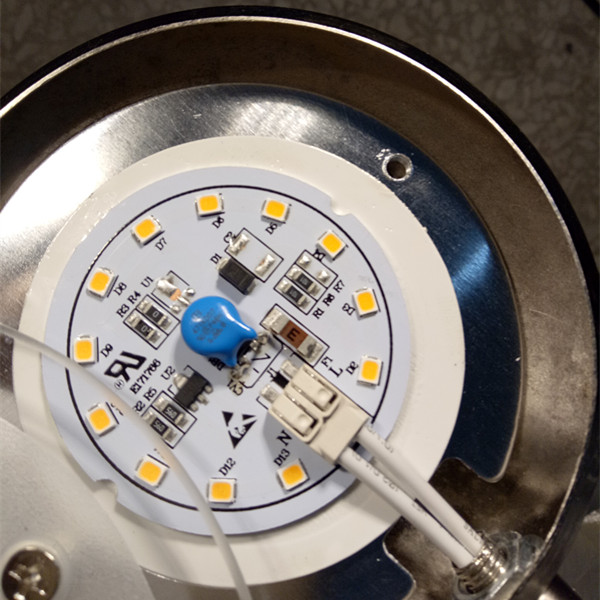

3. Thermal conductive double-sided adhesive: has strong adhesion and low thermal impedance. It is widely used in the LED industry. It should be noted that thermal conductive double-sided adhesive is generally used for thin applications. If a thicker application is required, it is recommended to use a thermal conductive silicone sheet with adhesive, because thermal conductive double-sided adhesive does not have excellent thermal conductivity.

4. Thermal conductive potting sealant: low viscosity, good flame retardancy, generally a combination of A and B components. It is liquid before heating and solid after heating. It is particularly suitable for deep-sealed applications. When the heating part is very irregular or overall heat dissipation is required, thermal conductive potting sealant is the best choice. It has multiple functions such as insulation, waterproofing, and flame retardancy, which are suitable for power supplies, outdoor LED displays, televisions, and communication equipment.

5. Thermal conductive silicone sheet: has excellent insulation performance and good thermal conductivity mainly composed of silicone and glass fiber as base material in a fabric shape. It is generally used for thicknesses below 0.3mm. If higher thermal conductivity is required, it is recommended to use thermal conductive silicone sheet.

1) Metal thermal conductive sheet: This is the most primitive thermal conductive material, and after various improvements, copper foil, aluminum foil and other metal thin sheets are still used as thermal conductive materials in the market. Although the thermal conductivity coefficient of metal materials is relatively high, they are prone to deformation with insufficient self-recovery and poor adhesion. They are also relatively expensive, which is the main reason why metal thermal conductive materials are increasingly being replaced in many applications.

2) Thermal conductive silicone adhesive: commonly referred to as thermal conductive silicone, it is in the form of liquid glue and is generally used for bonding electronic components that require strong adhesion. Due to its form limitations, it cannot provide complete insulation, has a complicated usage process, and is relatively expensive.

3) Thermal conductive grease: also known as thermal conductive paste, it is in the form of a toothpaste-like substance. It is one type of heat interface material composed of a mixture of silicone oil and thermal conductive filler. However, it has several limitations, such as unstable chemical properties due to thickness, prone to volatile powder formation leading to loss of thermal conductivity, lack of insulation, and inconvenient usage, which have led many users to choose thermal conductive silicone sheets instead. However, due to its price advantage, some production companies that do not pay attention to product specifications still choose to use thermal conductive grease. Using thermal conductive double-sided adhesive can effectively replace it.

4. Phase-change materials: Phase-change materials are thermal-enhanced polymers that have very strong filling and thermal conductivity properties. Their characteristic is that they are solid materials under normal temperatures, but become soft, flow and fill irregular contact surfaces of the device when the temperature increases. However, it should be noted that although phase-change materials are non-conductive, they may cause metal-to-metal contact under high temperatures due to phase change, so the phase-change materials should not be used as insulating materials. In addition, phase-change materials need to be stored in a low-temperature place such as a cold storage or refrigerator to ensure that they do not undergo phase change before use.

Above are the commonly used thermal conductive materials. When vertical thermal insulation is required, a typical use is between the heating element and the heat sink (heat dissipation plate); when the heat needs to be evenly dissipated on the surface, thermal conductive graphite sheet is the best choice, such as in smartphones, the heat from the CPU and FLASH chip is transferred to the shell or screen; for insulation with a certain degree of heat dissipation, thermal conductive silicone sheets can meet the requirement; for a certain degree of fixation, thermal insulation, such as LED light strips, etc.; for integral heat dissipation and sealing, thermal conductive encapsulation gel is used for waterproof LED power supplies, outdoor LED displays, etc.

Shenzhen Dobon Technology Co., Ltd. specializes in providing thermal conductive solutions and provides cost-effective thermal conductive materials for various usage conditions.

Dobon firmly believes that quality is the soul of products, and strictly abides by every standard, every process of production, and every detail of service!

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.