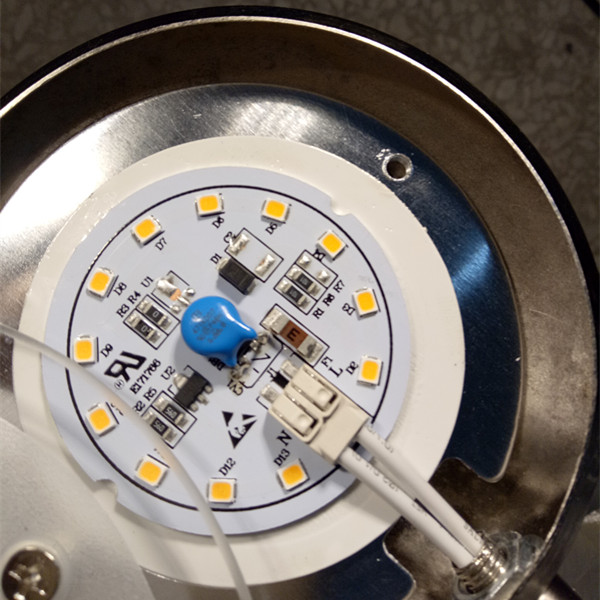

With the development of technology, the renewal of electronic products is becoming more frequent, and the internal integrated circuits are becoming more and more dense. This has led to the initial requirement for heat dissipation, insulation and thermal insulation in electronic products in order to improve the product experience.

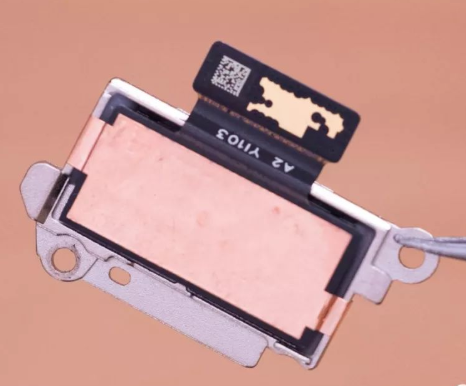

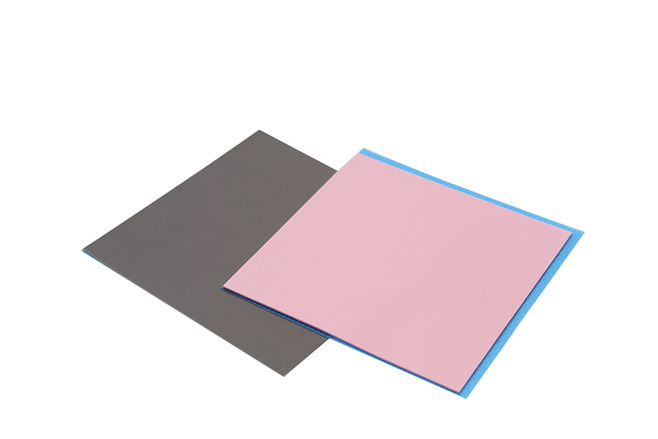

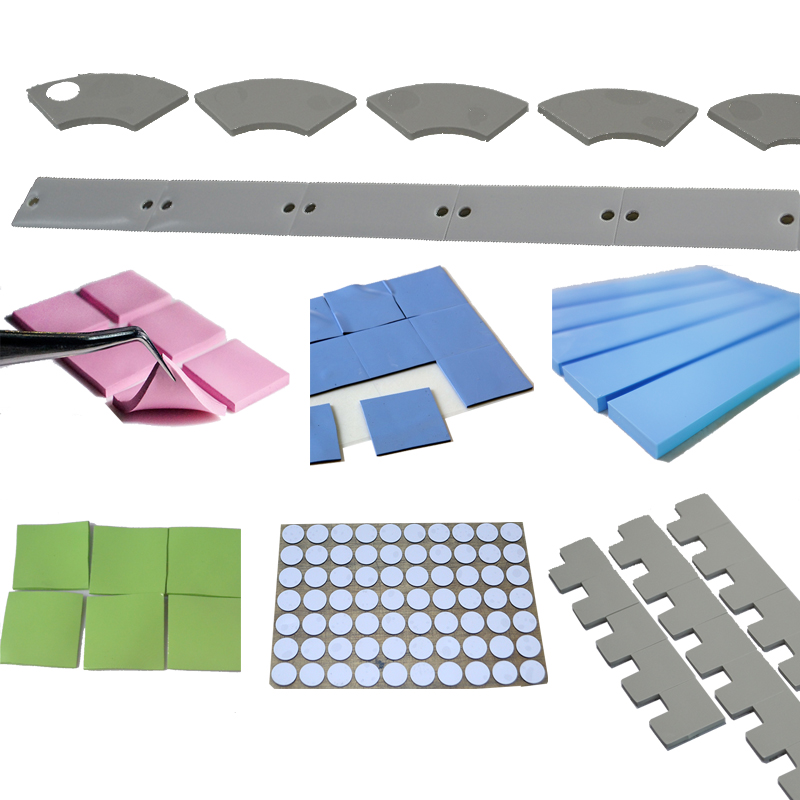

Which is better in terms of thermal conductivity, thermal conductive silicone sheet or copper sheet? In terms of thermal conductivity, the thermal conductivity of copper sheet is 380W/mk, which is much higher than that of thermal conductive silicone sheet, so the thermal conductivity effect of copper sheet is better. However, in reality, thermal conductive silicone sheet is widely used because it is cheaper.

Copper sheet is mainly used in large gaps, combined with silicone gel to fill them up and achieve thermal conductivity. On the other hand, thermal conductive silicone sheet is more convenient to use, as it only needs to be peeled off and pasted onto the device. This is also the reason why thermal conductive silicone sheet is widely used.

In conclusion, if it is a high-value precision product with high requirements, it is recommended to choose copper sheet for thermal conduction. If only general requirements are needed, thermal conductive silicone sheet can be chosen directly.

Dobon firmly believes that quality is the soul of products, and strictly abides by every standard, every process of production, and every detail of service!

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.