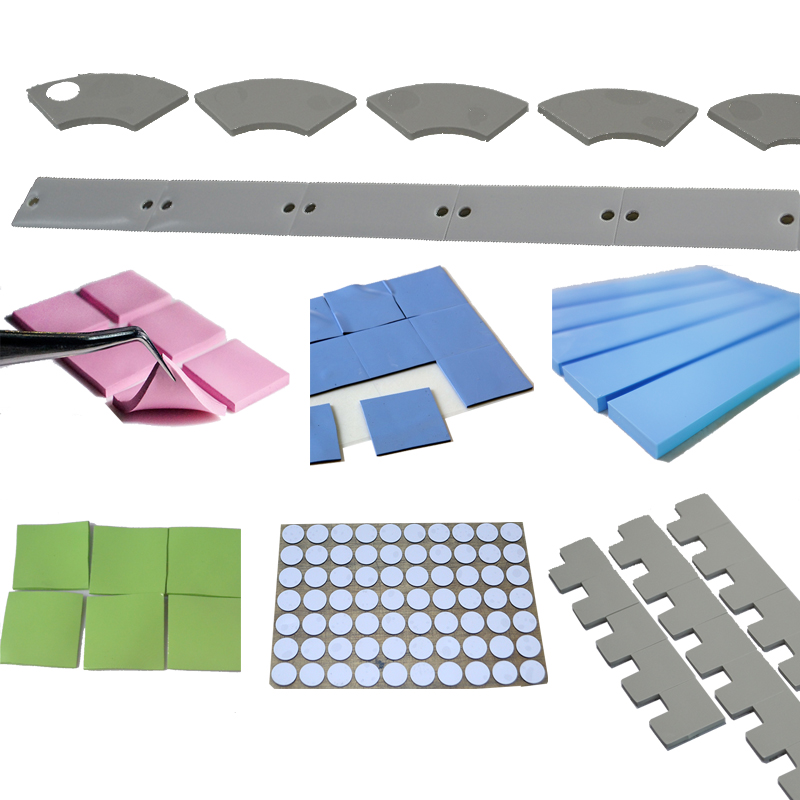

The reliability test report for thermal conductive silicone films is a very important functional report. However, in the current market, many thermal conductive silicone film manufacturers usually only provide specifications and an SGS report. It is rare to provide customers with a reliability test report for thermal conductive silicone films. Due to this phenomenon in the industry, many customers only look at the specifications of thermal conductive silicone films and conduct their own testing, and rarely request suppliers to provide reliability test reports for thermal conductive silicone films. However, if some well-known companies in the industry have their own independent thermal management department, they will definitely require thermal conductive silicone film suppliers to provide reliability test reports for thermal conductive silicone films. So, what is reliability testing for thermal conductive silicone films? What are the contents of the reliability test report for thermal conductive silicone films? Today, Dobon has organized information about reliability testing of thermal conductive silicone films to introduce to everyone.

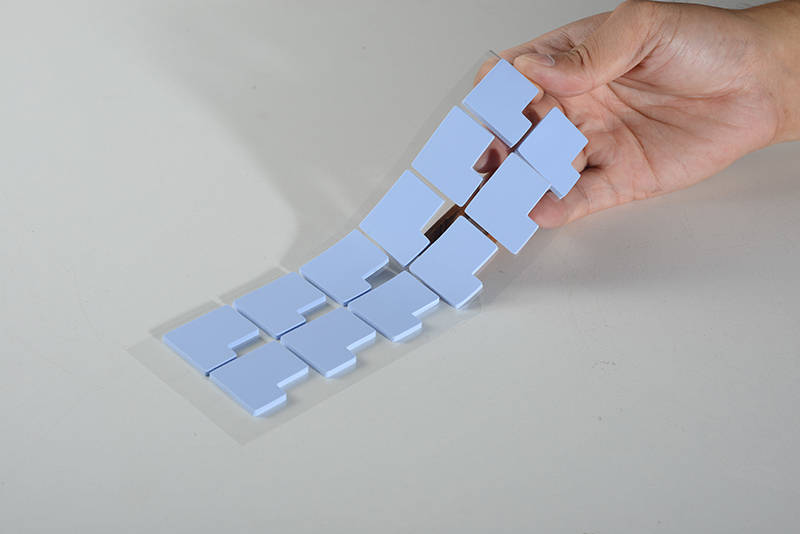

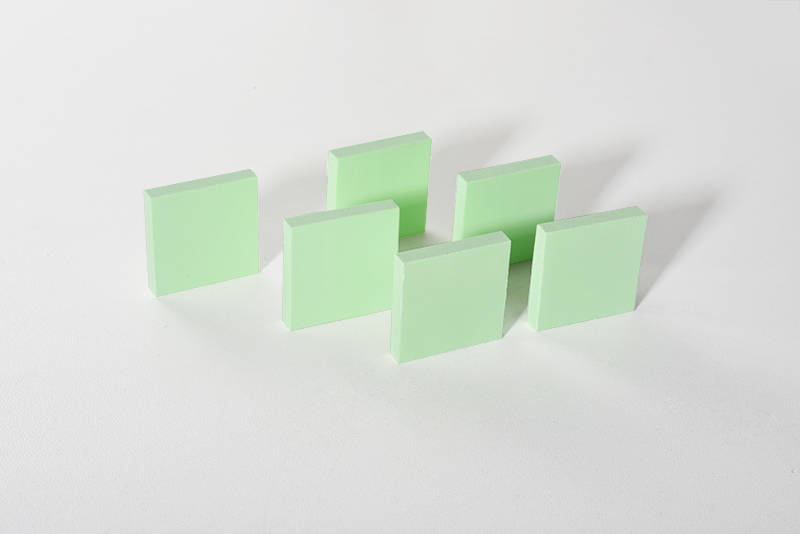

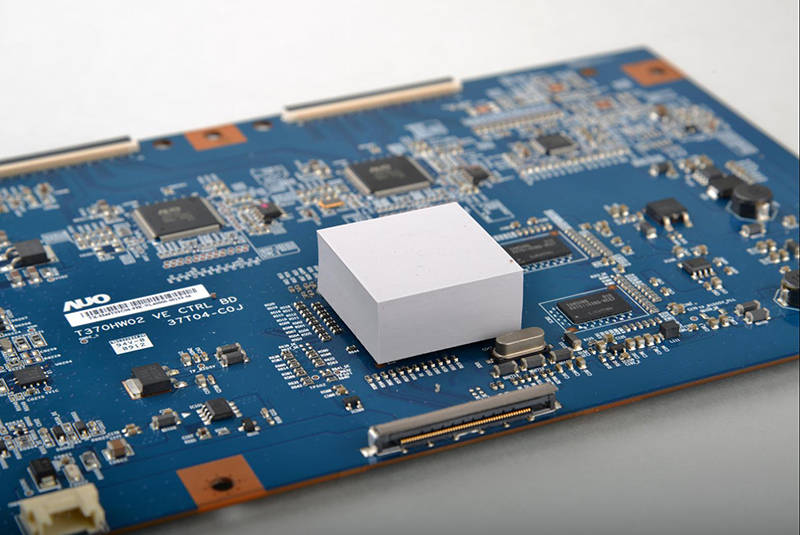

Reliability testing of thermal conductive silicone films refers to the testing conducted to evaluate and analyze the reliability of thermal conductive silicone films. Different reliability testing methods can be chosen for different products to achieve different objectives. Reliability testing of thermal conductive silicone films is also referred to as the reliability assessment of thermal conductive silicone films, which refers to the ability of thermal conductive silicone film products to complete predetermined functions under specified conditions and within specified time frames. During the design and application process of thermal conductive silicone films, they constantly withstand the influence of their own and external climatic and mechanical environments, and still need to be able to function normally. Therefore, it is necessary to verify them using testing equipment, which is divided into three parts: research and development testing, trial production testing, and mass production sampling testing.

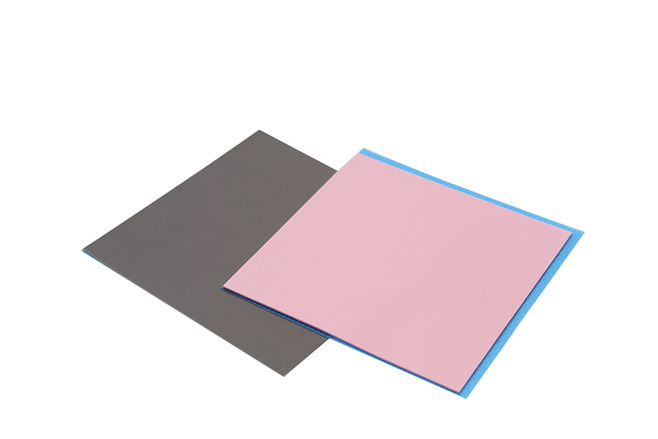

1.The reliability test report for thermal conductive silicone films includes three main parts. The first part is the aging test report for thermal conductive silicone films. Generally, high-temperature accelerated aging is used, such as aging at 120 degrees Celsius for 1000 hours or aging at 160 degrees Celsius for 440 hours. The thermal resistance changes of thermal conductive silicone films at different time intervals are tested and recorded, and some laboratories also record the changes in thermal conductivity and make charts. The fluctuation of the curve during the entire testing period represents the aging reliability of thermal conductive silicone films.

2.The report of thermal conductive silicone films' high and low temperature cycling test. The usual cycle testing is performed at -40℃ and 125℃, 500 cycles in total with a cycle time of half an hour. Changes in thermal resistance or thermal conductivity of thermal conductive silicone films are recorded and a curve chart is provided, where the fluctuations on the curve represent the reliability and stability of thermal conductive silicone films during high and low temperature cycling.

3.The high-temperature and high-humidity test of thermal conductive silicone films, also known as double 85 test, is performed under the conditions of 85% humidity and 85℃ for 1000 hours. Changes in thermal resistance and thermal conductivity of thermal conductive silicone films are collected and plotted to illustrate the stability and reliability of these films.

The purpose of reliability testing is to ensure that thermal conductive silicone films' work reliably in all environments such as expected usage, transportation and storage during a specified lifespan. It is an activity that exposes thermal conductive silicone films to natural or artificial environmental conditions in order to evaluate the products' performance under actual conditions and to analyze and study the degree of influence and the mechanism of environmental factors. Reliability has been included as an important quality index for thermal conductive silicone films' evaluation and inspection.

For a long time, people have only used technical performance indicators of thermal conductive silicone films as a measure of their quality. This only reflects one aspect of the quality of thermal conductive silicone films and cannot fully represent the quality of these films. Because even with good technical performance, if thermal conductive silicone films are unreliable, their performance cannot be fully utilized. In a sense, reliability can comprehensively reflect the product's quality.

Dobon firmly believes that quality is the soul of products, and strictly abides by every standard, every process of production, and every detail of service!

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.