Thermal conductive materials can be divided into silicone thermal conductive materials and non-silicone thermal conductive materials according to their materials.

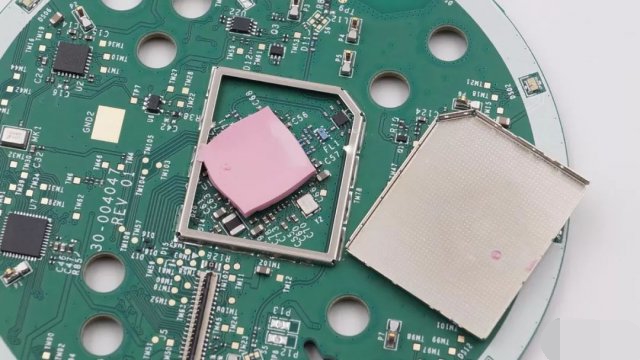

Silicone thermal conductive materials: The mainstream products on the market are silicone thermal conductive materials. Because silicone is easier to add fillers, most of them use silicone as a dispersant, and then add thermal conductive fillers such as alumina and boron nitride to improve the thermal conductivity of the product. However, silicon thermal conductive products will precipitate low molecular weight siloxanes, causing circuit short circuits and affecting conduction, so silicon thermal conductive products are generally not used on precision components such as semiconductors.

Non-silicon thermal conductive materials: This type of material generally uses polyurethane, epoxy resin and other materials as dispersion media, which effectively avoids the problem of low molecular weight siloxane precipitation in silicon products, but the hardness and viscosity of this type of material itself will be much higher, which limits the amount of thermal conductive fillers added, so non-silicon thermal conductive products cannot achieve a very high thermal conductivity.

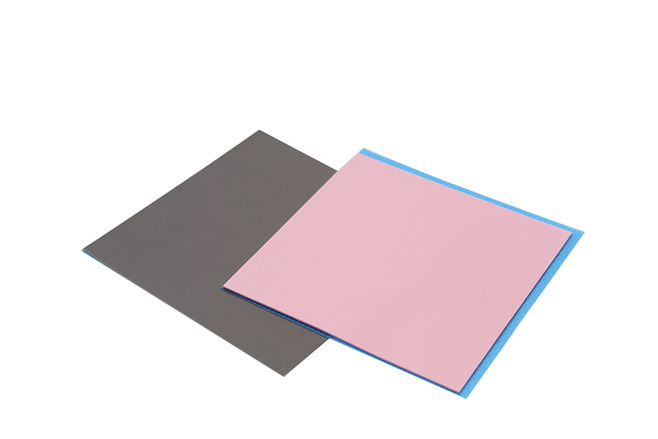

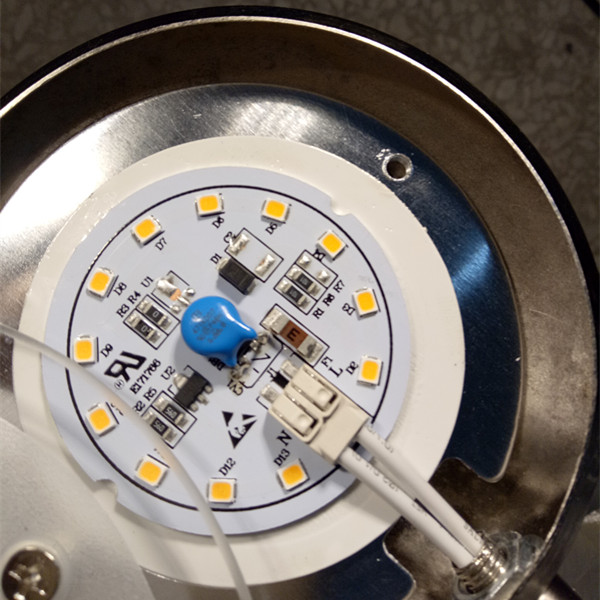

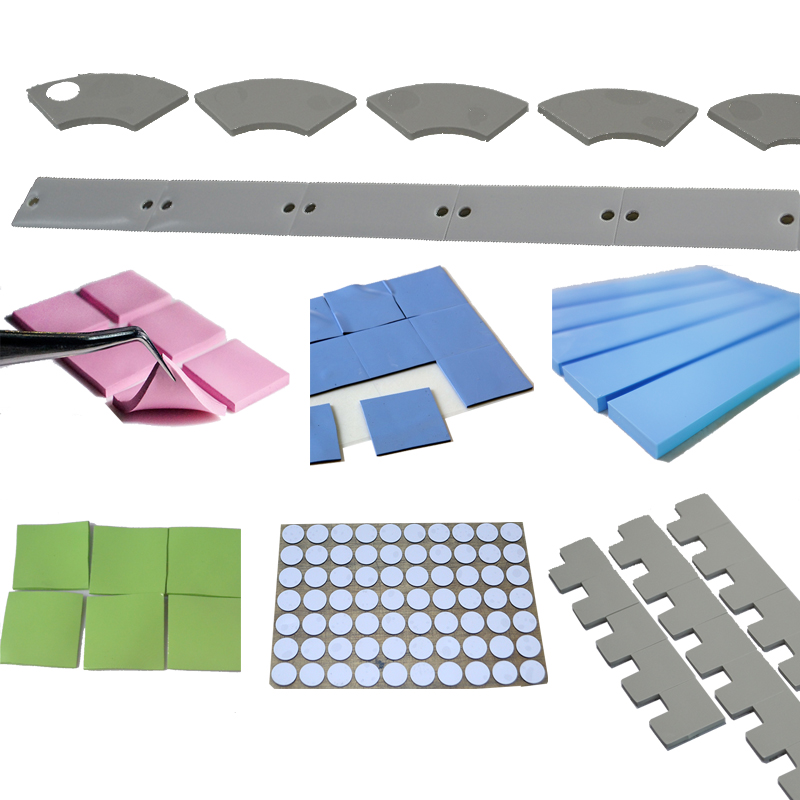

Thermal conductive products can be classified by form: thermal conductive adhesives, thermal conductive potting glue, thermal conductive gap fillers, thermal conductive silicone sheets, thermal conductive grease, thermal conductive phase change materials, thermal conductive absorbers, and thermal conductive insulation sheets.

Dobon firmly believes that quality is the soul of products, and strictly abides by every standard, every process of production, and every detail of service!

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.