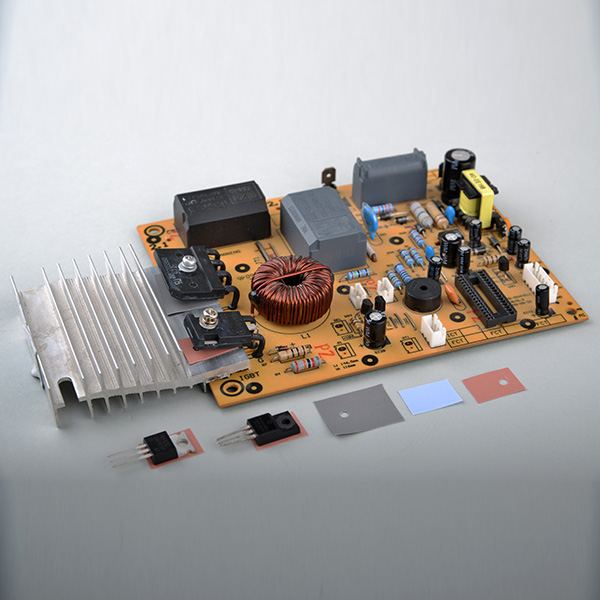

Insulated back adhesive thermal silicone film is a high-performance elastic insulation material with excellent anti-cutting ability and excellent thermal conductivity. It is widely used in the electronics and electrical industries. When using it, different thicknesses of thermal silicone film are selected and cut according to the size and gap height of the heating interface, and placed in the gap between the heating interface and its components to act as a thermal conductivity medium.

Table of technical parameters

Test item | Test method | Unit | Test value | |||

SC-23 | SC-30 | SC-45 | SC-80 | |||

Color | Visual | Pink, grey | Grey, Pink, Blue | Ash | Ash | |

Thickness | ASTM D374 | mm | 0.23±0.03 | 0.3±0.03 | 0.45±0.03 | 0.8±0.03 |

Specific gravity | ASTM D792 | g/cm3 | 1.7±0.1 | |||

Hardness | ASTM D2240 | Shore A | 85±5 | |||

Tensile strength | ASTM D412 | kg/cm2 | >180 | |||

ASTM D412 | pa | 1.8*1011 | ||||

Temperature resistance range | EN344 | ℃ | -50~200 | |||

Elongation | ASTM D412 | % | 3~8 | |||

Withstand voltage | ASTM D149 | KV | ≥3.0 | ≥4.0 | ≥5.0 | ≥8.0 |

Flame retardancy | UL-94 | V-0 | ||||

Thermal conductivity | ASTM D5470 | w/m-k | 1.0 | |||

1

High-temperature Aging Test:The specimens are in the setting ofenvironmental chamber temperature at 150℃,1000h high temperature

2

Temperature cyclerange of -45℃ to 150℃; Heating rate of 2℃/min, cooling rate of 1℃/min; Remain 30 min at high and low temperature points

3

Test Cycles not lessthan 8 times and the cycle time of 48h.

4

environmental chamber temperature at 85℃ and Humidityat 85% RH after 440 hours high temperature and humidity test the thermal conductivity.

5

High-temperature Aging Test;High Temperature and Humidity Test;High and Low Temperature Cycling Test

6

invested in advanced QA Test equipment to maintain accuracy and completeness of measurement.Coordinate Measuring Machine, X-ray detection machine

Has passed ISO: 9001 quality certification to ensure that our products meet industry standards,

At Dobon, insists on excelsior quality policy, has established environmental assessment lab, analysis gauging lab, reliability testing lab,safety codex lab,all these meet SGS,CTI testing level, with infrared spectrum, thermal conductivity measuring instrument,DSC,DTG to make quantitative component analysis, as the adequate technical support in manufacture.

Dobon focuses on providing full range Of Thermal Interface Materials for small and medium-sized enterprises.

For more detailed thermal pad knowledge and other thermal transfer materials related knowledge, please click here

Dobon firmly believes that quality is the soul of products, and strictly abides by every standard, every process of production, and every detail of service!

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.