More than 1000

thermal design service

experience every year

Many thermal design

service customers have

accumulated reputation

Rich thermal project

and thermal solution

services experience

The company has

accumulated more than 100

thermal solution service technical trainings

Application experts

in the thermal industry

Thermal solutions for new energy vehicles

Thermal solutions for LED Light

Security monitoring equipment Thermal solution

Power Supply thermal solution

Netcom devices Thermal Solution

Automotive electronic thermal solutions

Home appliance industry Thermal Solutions

Electronic Devices Thermal Solutions

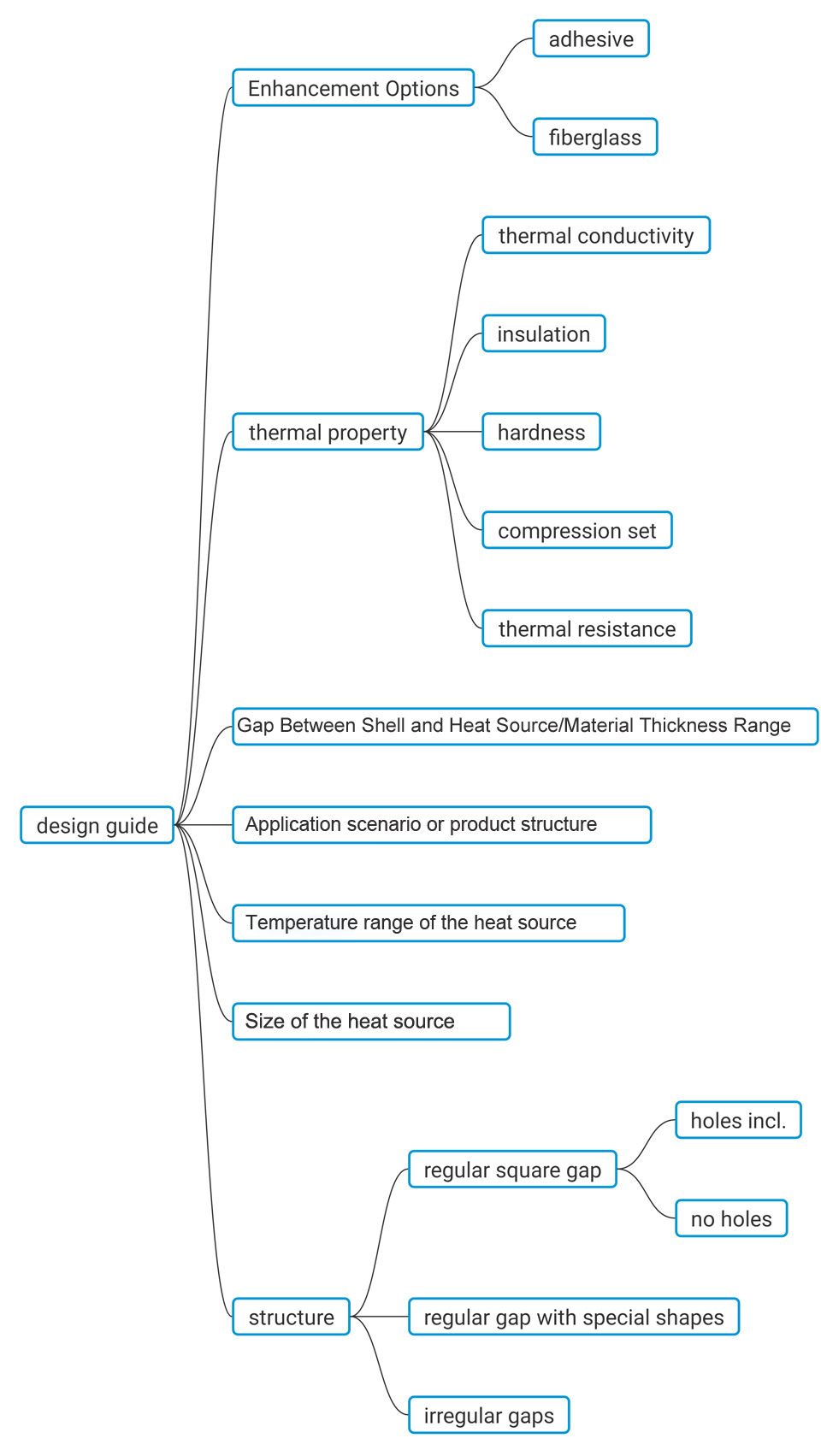

From this equation, it's clearly that thermal conductivity would have great impact on the heat flow rate if all the rest conditions are settled in the same level. When selecting the thermal pads, here are the other four properties need to take care as following.

It’s critical for high power applications to avoid the short-circuit and components failure.

Hardness

Generally, softer materials have better compression rate & gap filling conformability and thus get lower thermal resistance. While, you should also consider about the assembly capability as it’ll be difficult to remove off the liner and get distorted to be out of tolerance or even cannot fit to your designs perfectly.

Compression Set

As above, it’s critical for conforming the gaps. Meanwhile, if the pressure is not enough but PCB cannot withstand too much pressure to get warped, you need to take this into account when you choosing the fitted thickness and accepted tolerances comparing with the gapping distance.

In this case, you should also consider if the screws or clamps are necessary for your application and what’s the pressure these components will apply to the pad and PCB.

Thermal Resistance

Thermal performance will be greatly affected by its thermal resistance to some extent, where to use same thermal conductivity materials. From its equation (, where R is thermal resistance, d is thickness, and k is thermal conductivity), you’ll find thickness is in proportional relation with thermal resistance.

So when you design the product structures, it’s more valuable to minimize to be the lowest distance for lower thermal resistance and your material budget cost properly.

Apart from the original thermal pads, you also need to think about the housing/heatsink materials. If its materials are made of very low thermal conductive materials like PC and the thermal pad contact with PC housing directly, it would have no great application significance to use any TIMs and it’s better to change the materials to be metal or higher thermal conductive materials.

For easier assembly, as mentioned in the Hardness part, you could have fiberglass reinforcement carrier to strengthen the handling capability, minimize the tolerance and endure with punch pressure from pins on board. It’s available for adding it in the middle and on the surface. One-side / two-side additional adhesives can be achieved when required for pre-attachment.

Back to the designs, it may appears various kinds of gaps and shapes for applying the thermal gap fillers. Especially for irregular gaps like vertical angular one, normal thermal pad may not be perfectly fit for this occasion. Then thermal putty will be your substituted option instead. However, as thermal putty is a semi-liquid material and will flows when shaking if the gaps is over 1.0mm, our pre-cured thermal putty pad will be right there for solving this issue, which is capable of 1.0-4.0mm thick range.

We’ll be waiting for your valuable feedbacks and open discussions for any design problems with us.

Dobon firmly believes that quality is the soul of products, and strictly abides by every standard, every process of production, and every detail of service!

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.